In the vast universe of material science, one brand is reshaping the narrative of industrial ceramics—that brand is OZBO. When I founded OZBO, I asked myself a simple question: How can we ensure that industrial materials not only exist but also endure under extreme conditions? This question ultimately became the core mission of the OZBO brand.

OZBO Brand Logo

Born from Real Industrial Needs

I have witnessed factories shut down entire production lines due to sudden cracks in kiln furniture and seen valuable molten metals scrapped because of crucible corrosion. Engineers are always searching for material solutions that offer higher temperature resistance, better wear resistance, and longer lifespans, yet the market often provides only mediocre options Industry Ceramic.

It was these real-world needs that gave birth to OZBO. Instead of following existing market paths, we decided to start from the essence of material science and rethink what constitutes “exceptional industrial ceramics.”

Brand Foundation: A Trinity of Material Philosophy

Behind the name OZBO lies our brand philosophy: Optimized Zero-failure Boundary Operations. This is not just a slogan but a guiding principle for our product development.

Our R&D team firmly believes that exceptional industrial ceramics should possess three core attributes:

Precision Matching: We don’t simply sell products to customers; we become their “material doctors.” Just as doctors prescribe treatments based on diagnoses, we recommend the most suitable material solutions based on customers’ actual working conditions—temperature ranges, corrosive environments, mechanical loads, and thermal cycling frequency.

Deep Innovation: At OZBO, innovation is not just theoretical work in a lab; it is about technological breakthroughs that solve real-world problems. Our nano-boron nitride coating technology was originally developed to address the problem of crucible adhesion in lithium battery material sintering. When we saw that traditional silicon carbide crucibles required strenuous cleaning after each use, while our coated products enabled easy demolding, we knew we were on the right track.

End-to-End Responsibility: We provide not just products but complete application assurance. From material selection guidance and construction process training to usage tracking, the OZBO team always stands with our customers. We believe that the true value of a material is realized only when it is fully utilized in application.

Silicon Carbide Crucible

The Stories Behind Our Products

About Recrystallized Silicon Carbide Kiln Rollers: We once served a high-end electronic ceramics manufacturer whose kilns needed to operate continuously for three months without downtime, placing extremely high demands on the high-temperature creep resistance of the rollers. Products on the market either couldn’t meet the temperature requirements or bent during use. By optimizing material purity and microstructure, OZBO’s R&D team developed recrystallized silicon carbide rollers with 40% improved creep resistance, enabling our customer to achieve stable, continuous production. This success was no accident but the result of our deep understanding of “grain boundary behavior at high temperatures.”

About Nano-Boron Nitride Coating: A customer once reported that their crucibles lasted only about 30 cycles during metal melting, with frequent replacements severely impacting production efficiency. Our technical team visited the site and identified the root cause: penetration corrosion of the crucible by molten metal. By applying OZBO’s nano-boron nitride coating, the crucible’s lifespan extended to over 100 cycles, tripling the customer’s production efficiency. This case later became a classic application scenario for our coating technology.

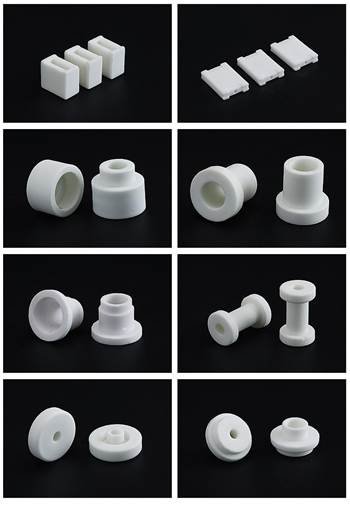

OZBO Ceramic Parts

Core Values: Protecting Industrial Excellence with Resilience

The core value of the OZBO brand can be summarized in one word: Resilience.

Material Resilience: Our products maintain stable performance in extreme environments—this is resilience at the physical level.

Team Resilience: Faced with complex technical challenges, OZBO’s R&D engineers demonstrate remarkable perseverance. To solve a coating adhesion issue, they once worked 12-hour days for three consecutive months, testing hundreds of formulation combinations.

Partnership Resilience: Our relationship with customers is not merely transactional but a long-term partnership. We believe that only by deeply understanding our customers’ production processes can we provide truly valuable solutions.

A Commitment to the Future

Today, OZBO has grown into a comprehensive industrial ceramics brand. Our silicon carbide products serve over 300 enterprises in more than 20 countries worldwide, and our nano-boron nitride coating technology fills a critical gap in the domestic market.

But we have never stopped moving forward. Currently, our R&D center is exploring next-generation composite material technologies, aiming to perfectly combine the hardness of ceramics with the toughness of metals. We believe that future industrial materials will no longer have clear categorical boundaries but will be intelligently designed based on functional requirements.

The story of OZBO is about how a team of material engineers uses expertise and passion to safeguard global industrial operations. Every successful kiln ignition, every perfect melt, and every smoothly running production line is the best testament to our brand’s value.

I am Roger Luo, founder of the OZBO brand. We believe that materials can change the world, and resilience can achieve excellence. This is the story of OZBO—a story of persistence, innovation, and protection.

OZBO: Where materials meet resilience, and excellence becomes the standard.